Custom Tank Top Manufacturer: A Complete 2025 Guide

- Share

- Issue Time

- Sep 11,2025

Summary

Looking for a reliable custom tank top manufacturer? This complete 2025 guide covers everything from OEM & ODM services, private label options, fabrics, MOQ, and bulk production to help brands, wholesalers, and startups find the best tank top supplier.

Tank tops may look like simple apparel pieces, but when it comes to manufacturing, every detail matters—fabric selection, GSM (grams per square meter), knitting structure, seam types, shrinkage control, labeling, and packaging. For brands, wholesalers, and startups, choosing the right custom tank top manufacturer ensures consistency, durability, and the ability to scale production.

In this guide, we’ll cover everything you need to know about working with a reliable tank top factory—from OEM/ODM services, customization options, technical specifications, and quality control, to supplier evaluation.

Why Work with a Custom Tank Top Manufacturer?

1. Technical Expertise

• Professional factories handle pattern making, grading, marker making, and cutting with precision.

• Skilled in both knit and woven tank tops, providing accurate Bill of Materials (BOM).

2. Cost & Lead Time Optimization

• Bulk fabric sourcing and automated sewing lines reduce per-unit costs.

• Efficient production scheduling ensures shorter lead times.

3. OEM & ODM Support

• End-to-end services: prototype sample → PP sample → pilot run → bulk production.

• Branding services: custom labels, tags, packaging, and private label solutions.

4. Quality Assurance & Compliance

• Many factories hold certifications such as OEKO-TEX, GOTS, BSCI, Sedex.

• Familiar with restricted substances lists (RSL) and international testing standards.

Types of Tank Tops You Can Customize

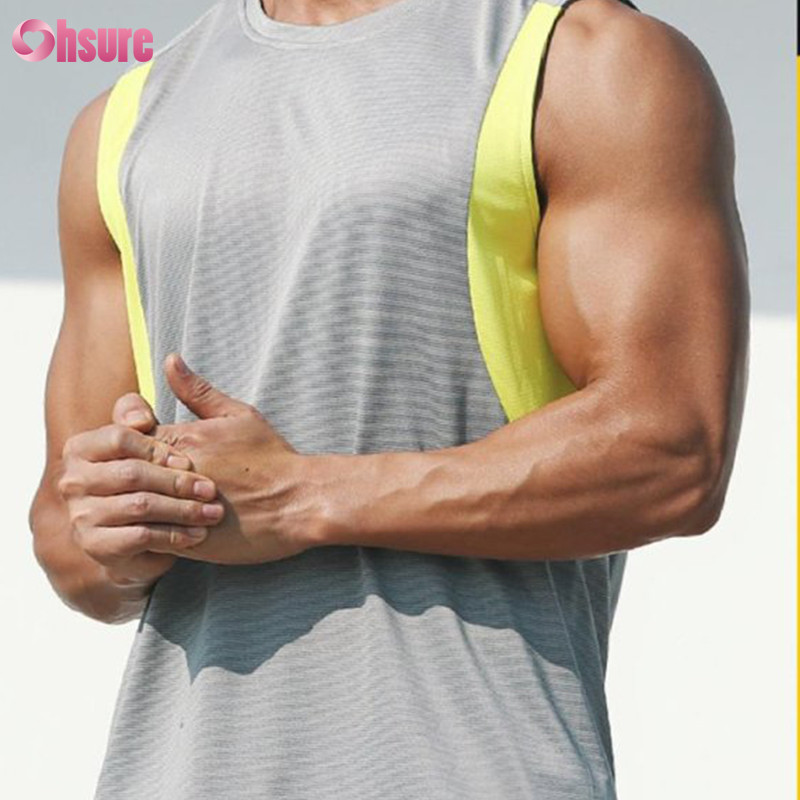

Men’s Tank Top Manufacturer Options

• Fabrics: single jersey cotton, cotton blends, modal.

• GSM: 160–220 g/m² for casual comfort.

• Key features: ribbed necklines, double-needle hem stitching.

• Key features: ribbed necklines, double-needle hem stitching.

Women’s Tank Top Manufacturer Options

• Styles: slim fit, racerback, fashion cuts.

• Add-ons: adjustable straps, decorative prints, embroidery.

Sports & Gym Tank Top Manufacturer

• Fabrics: polyester/spandex blends, 4-way stretch, moisture-wicking.

• Specs: air permeability, quick-dry, anti-microbial finishing.

• Techniques: flatlock seams, laser cutting, bonded hems.

Fashion & Streetwear Tank Tops

• Oversized silhouettes, garment dye, enzyme wash, distressed looks.

• Printing: large-format screen prints, DTG (direct-to-garment), heat transfer.

Sustainable & Eco-Friendly Tank Tops

• Materials: organic cotton, bamboo, Tencel, recycled polyester (rPET).

• Certifications: GOTS, OEKO-TEX, RCS.

• Factories with traceable supply chains and eco-friendly dyeing/finishing.

Key Features to Look for in a Tank Top Factory

1. Fabric Parameters

• GSM tolerance (±5%).

• Yarn count & composition (e.g., 30s combed cotton, 75% polyester / 25% elastane).

• Knitting structure: single jersey, rib, interlock, mesh.

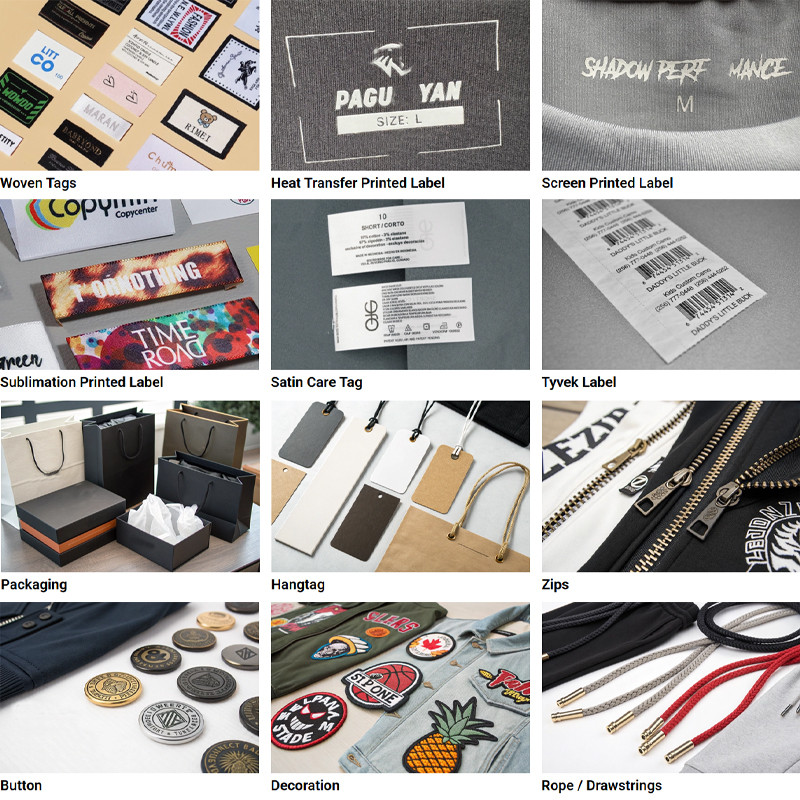

2. Customization Options

• Printing: screen printing, sublimation, DTG, heat transfer.

• Embroidery: stitch density, backing type, thread color (Pantone).

• Branding: woven labels, care labels, hangtags, custom packaging.

3. Fit & Grading

• Size specifications with tolerances.

• Plus-size or oversized grading rules.

4. MOQ (Minimum Order Quantity)

• Standard tanks: 300–500 pcs MOQ.

• Complex prints/embroidery: usually 1000 pcs MOQ.

• Small MOQ suppliers are ideal for startups and private label brands.

Custom Tank Tops for Different Needs

Gym & Workout Tank Tops

• Moisture-wicking, breathable, durable for intense activities.

• Often require lab tests for elongation & recovery rates.

Private Label Tank Tops for Brands

• Full OEM/ODM services with brand labels, swing tags, and packaging.

• Factories offer tech pack development based on your design.

Blank Tank Tops for Printing

• Bulk orders for screen printing or heat transfer shops.

• Typically available in cotton and polyester blends.

Bulk Tank Top Manufacturer for Wholesalers

• Tiered pricing models (e.g., 1000 pcs vs. 5000 pcs).

• Ability to produce standard cuts at competitive FOB prices.

How to Choose the Best Tank Top Supplier

1. Evaluate Experience & Certifications

• Check for BSCI, WRAP, OEKO-TEX, ISO certifications.

2. Request Samples

• Prototype → Fit sample → PP sample.

• Ensure consistency between samples and bulk production.

3. Compare Production Capacity & Lead Time

• Ask about daily output (pcs/day) and available production lines.

4. Quality Control System

• Does the factory use AQL 2.5/4.0 inspection?

• Are reports traceable in ERP/MES systems?

5. Communication & Service

• Responsive merchandisers.

• Clear English/Chinese tech pack communication.

Benefits of Working with a China Tank Top Manufacturer

• Cost Advantage: Competitive pricing with flexible MOQs.

• Material Variety: Access to a wide network of fabric mills.

• Speed: Shorter lead times due to high-capacity factories.

• OEM/ODM Strength: Strong sample development and customization ability.

FAQ About Custom Tank Top Manufacturing

Q1: What is the typical MOQ for custom tank tops?

A: Basic orders can start at 100 pcs. Complex prints or custom fabrics often require 1000 pcs+.

Q2: How long does production take?

A: Samples: 7–14 days. PP sample: 3–7 days. Bulk orders: 25–35 days, depending on order size.

Q3: Can I order small quantities with custom logos?

A: Yes, but expect a higher unit price due to setup costs (screen mesh, embroidery boards).

Q4: What fabrics are best for gym vs. casual tanks?

A: Gym tanks → polyester/spandex blends with quick-dry. Casual/fashion tanks → cotton, modal, or blends.

Q5: How do I start a private label tank top brand?

A: Partner with an OEM/ODM factory, prepare a detailed tech pack, request samples, confirm PP, and place bulk orders.

Conclusion

Finding the right custom tank top manufacturer is not just about producing garments—it’s about building a partnership that ensures quality, consistency, and scalability. Whether you’re a startup testing the market with small MOQ or an established brand seeking bulk production, a professional manufacturer can support you with fabric sourcing, pattern development, OEM/ODM customization, and strict QC systems.